| Sprache umschalten: |

home |

The Rohloff Speedhub internally-geared bicycle hub is a beautiful piece of equipment. Because of its reliablity, it is famed amongst world traveling bike tourists. These folks have taken Speedhubs to the remotest places on earth, places so remote that bringing several kgs of spareparts makes sense: Inner tubes, tires, spokes, chains, brake shoes, BB, pedals, cable ties, insulating tape ..

The Rohloff Speedhub internally-geared bicycle hub is a beautiful piece of equipment. Because of its reliablity, it is famed amongst world traveling bike tourists. These folks have taken Speedhubs to the remotest places on earth, places so remote that bringing several kgs of spareparts makes sense: Inner tubes, tires, spokes, chains, brake shoes, BB, pedals, cable ties, insulating tape ..The guys at Rohloff know this, so they have designed the sprocket of the Speedhub to be reversible: Once it's worn down, take it off and put it on reversely, then just ride on. No need to carry a spare, which is a great weight-saving concept. But have you actually ever reversed your speedhub sprocket ? Without Rohloff's special sprocket tool it's easy to spoil the hub and not get the sprocket off at the same time.

Now Rohloff's sprocket tool (part no. 8501) is quite solid and not exactly weight-optimized (52g), chances are high you've left it at home. So what to do if you're far from any Rohloff dealer, your sprocket is badly worn down and you need to change or reverse it ? This page may help.

Disclaimer:

This is a personal web page and not a Rohloff Speedhub service manual. Actually, what you find here is quite in contrast to the official service recommendations and there's a certain chance you damage your Speedhub when trying to remove the sprocket in the way described below. While the suggested approaches work for the author, they are not guaranteed to be workable or safe for you or your gear. If you decide to follow these instructions, do so at your own risk

Take your time, if you don't want a result like the one pictured. A washer completes the sprocket tool. Total weight (w/ washer): 46g

It's important that the tool is secured to the Speedhub axle. This is because the tool must not tilt or slip while a high force is being applied.

The sprocket is usually very tight but with a chain whip, wrench, work gloves and some force, it can be loosened. The sprocket has a standard thread, so in normal operation the chain pulls it onto the hub while counterclockwise rotation removes it.

The sprocket is usually very tight but with a chain whip, wrench, work gloves and some force, it can be loosened. The sprocket has a standard thread, so in normal operation the chain pulls it onto the hub while counterclockwise rotation removes it.

If the sprocket absolutely won't come off, if you got the direction right, try longer levers. For some people it's easier to lock the sprocket tool in a well-anchored vice, then pull on the chain whip with both hands. If nothing works, well, ask a real man for help.

Eventually you'll get that sprocket off.

By the way, turning the Speedhub over with the sprocket off creates an oil spill.

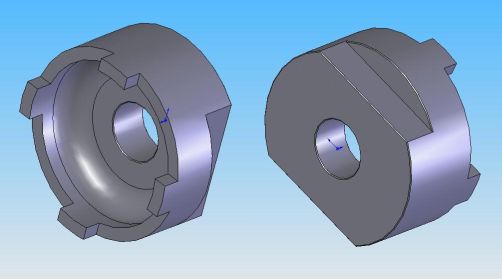

Not all parts of the world are so remote that you need to do with a hack saw, a file and a vice alone. In a place with Internet cafes and industrial parks, why not go for this much nicer sprocket tool on the right.

Not all parts of the world are so remote that you need to do with a hack saw, a file and a vice alone. In a place with Internet cafes and industrial parks, why not go for this much nicer sprocket tool on the right.How To:

Now here's the output of the CNC machine !

Now here's the output of the CNC machine !Nearly as nice as the orignal Rohloff sprocket tool, while custom-CNC makes it more expensive. In exchange for this you get it now, no need to wait for shipping from Germany, no discussion with customs

Use it in the same way as solution no.1